Kupaka kwa matepi

1, nthunzi makutidwe ndi okosijeni: ndikupeza mu kutentha kwa madzi nthunzi, pamwamba pa mapangidwe filimu okusayidi, ozizira adsorption ndi zabwino, angathandize kuchepetsa mikangano, kuteteza mpopi ndi kudula zinthu pakati pa chomangira, oyenera. pokonza zitsulo zofatsa.

2, nitriding chithandizo: wapampopi padziko nitriding, kupanga pamwamba kuumitsa wosanjikiza, oyenera processing chitsulo kuponyedwa, zotayidwa ndi zinthu zina pa kuvala chida.

3, nthunzi + nitriding: ubwino wokwanira wa ziwirizi.

4, TiN: zokutira zagolide zachikasu, kuuma bwino kwa kuyanika ndi kutsekemera, ndi ntchito yomatira yomatira ndi yabwino, yoyenera kukonza zida zambiri.

5, TiCN: zokutira buluu imvi, kuuma pafupifupi 3000HV, kukana kutentha kwa 400 ° C.

6, TiN + TiCN: zokutira zachikasu zakuda, zokhala ndi kuuma bwino kwa zokutira ndi mafuta, oyenera kukonza zida zambiri.

7, TiAlN: zokutira buluu imvi, kuuma 3300HV, kutentha kukana mpaka 900 ° C, angagwiritsidwe ntchito pokonza mkulu-liwiro.

8, CrN: zokutira siliva imvi, ntchito mafuta ndi apamwamba, makamaka ntchito pokonza zitsulo zopanda chitsulo.

Kuphimba kwapampopi kumakhudza kwambiri magwiridwe antchito a mpopi, koma pakadali pano, opanga ndi opanga zokutira amagwirizana kuti aphunzire zokutira zapadera, monga LMT IQ, Walther THL, ndi zina zambiri.

Zinthu zomwe zimakhudza kugogoda

A. Kugogoda zida

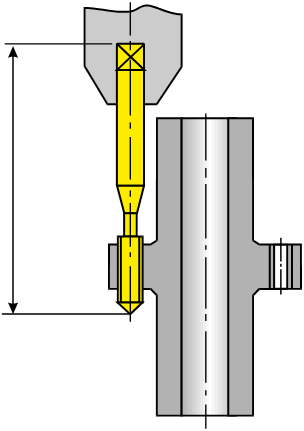

1. Chida cha makina: imatha kugawidwa m'njira zowongoka komanso zopingasa.Pogogoda, ofukula ndi yabwino kuposa kukonza yopingasa, ndipo kukonza kopingasa kuyenera kuganizira ngati kuzizirira ndikokwanira.

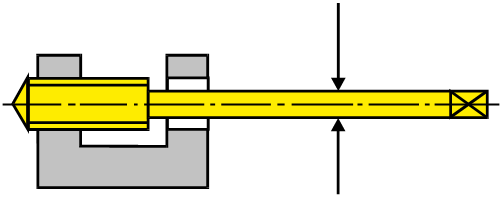

2, kugogoda shank: kugogoda kumalimbikitsidwa kuti mugwiritse ntchito shank yapadera, kukhazikika kwa makina, kukhazikika kwabwino kumasankhidwa posankha shank yolumikizira yolumikizana, m'malo mwake, momwe mungathere kusankha chosinthika cholumikizira shank ndi axial / radial compensation.Gwiritsani ntchito ma square drive ngati kuli kotheka, kupatula ma taps ang'onoang'ono (

3. Kuziziritsa zinthu: pogogoda, makamaka extrusion matepi, chofunika kwa ozizira ndi mafuta > kuzirala;Pakugwiritsa ntchito kwenikweni, zitha kukonzedwa molingana ndi momwe zida zamakina zimagwirira ntchito (pogwiritsa ntchito emulsion, tikulimbikitsidwa kuti ndendeyo ikhale yayikulu kuposa 10%).

B. Chogwirira ntchito chiyenera kukonzedwa

1. Zinthu ndi kuuma kwa workpiece kukonzedwa: kuuma kwa workpiece zinthu ayenera kukhala yunifolomu.Nthawi zambiri sizovomerezeka kugwiritsa ntchito matepi pokonza chogwiriracho kuposa HRC42.

2, kubowola pansi: kapangidwe ka dzenje pansi, sankhani pang'ono yoyenera;pansi dzenje dimensional kulondola;Pansi dzenje khoma misa.

C. Kusintha magawo

1, liwiro: liwiro amaperekedwa pamaziko a mtundu wa mpopi, zinthu, kukonzedwa zinthu ndi kuuma, ubwino ndi kuipa kwa zida pogogoda.

Nthawi zambiri amasankhidwa molingana ndi magawo operekedwa ndi wopanga matepi, liwiro liyenera kuchepetsedwa pamikhalidwe iyi:

▶ Kukhazikika kwa zida zamakina ndikosavuta;Kuthamanga kwakukulu;Kuzizira kosakwanira;

▶ Zida zokhomera kapena zolimba sizikhala zofanana, monga zolumikizira;

▶ Pompopo amatalikitsidwa, kapena ndodo yowonjezela;

▶ Kuzizira, kuzizira kunja;

▶ Kuchita pamanja, monga kubowola benchi, kubowola miyala, ndi zina zotero;

2, chakudya: kugunda molimba, chakudya = 1 phula/kutembenuka.

Kubowoleza kosinthika, komanso kusinthika kwa chipukuta misozi ndikokwanira:

Kudyetsa = (0.95-0.98) phula/kusintha.

Malangizo ena pakusankha tap

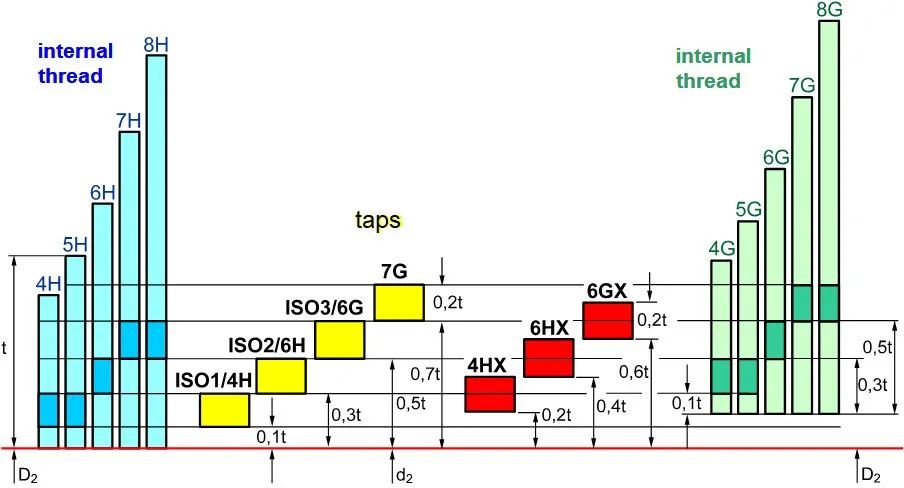

A. Kulekerera kwa matepi a magiredi olondola kwambiri

Maziko osankhidwa: osati molingana ndi giredi yolondola ya ulusi woti upangidwe kuti usankhe ndikuzindikira giredi yolondola ya mpopi

▶ Zida ndi kuuma kwa chogwirira ntchito;

▶ Zipangizo zamakina (monga momwe makina amagwirira ntchito, chogwirira, mphete yozizirira, ndi zina);

▶ Kupopa komweko ndikolondola komanso zolakwika zopanga.

Mwachitsanzo: processing 6H ulusi, mu processing zitsulo, akhoza kusankha 6H mwatsatanetsatane mpopi;Mu ndondomeko ya imvi kuponyedwa chitsulo, chifukwa awiri m'mimba mwake wa mpopi kuvala mofulumira, kukulitsa dzenje wononga ndi yaing'ono, choncho ndi koyenera kusankha 6HX mwatsatanetsatane mpopi, moyo adzakhala bwino.

Zindikirani kulondola kwa matepi aku Japan:

▶ Kudula kampopi OSG kumagwiritsa ntchito makina olondola a OH.Mosiyana ndi muyezo wa ISO, OH mwatsatanetsatane dongosolo amakakamiza lonse kulolerana bandi m'lifupi kuchokera malire otsika, aliyense 0.02mm monga mulingo wolondola, wotchedwa OH1, OH2, OH3, etc.

▶ Extrusion tap OSG imagwiritsa ntchito RH mwatsatanetsatane dongosolo, RH mwatsatanetsatane dongosolo adzakakamiza lonse kulolerana m'lifupi kuchokera malire otsika, aliyense 0.0127mm monga mulingo wolondola, wotchedwa RH1, RH2, RH3 ndi zina zotero.

Chifukwa chake, posintha kampopi wolondola wa OH ndi tapi yolondola ya ISO, 6H siyenera kuonedwa ngati pafupifupi yofanana ndi mulingo wa OH3 kapena OH4.Iyenera kutsimikiziridwa ndi kutembenuka kapena molingana ndi mkhalidwe weniweni wa kasitomala.

B. Kunja kwa mpopi

1. Pakali pano, omwe amagwiritsidwa ntchito kwambiri ndi DIN, ANSI, ISO, JIS, etc.

2, malingana ndi zofunikira zosiyanasiyana za kasitomala kapena zinthu zomwe zilipo kuti musankhe kutalika koyenera, kutalika kwa tsamba ndikuwongolera kukula kwake

3. Kusokoneza panthawi yokonza;

Dinani kusankha zinthu zisanu ndi chimodzi zofunika

1, mtundu wa processing ulusi, miyeso, British, American, etc.;

2. Mtundu wa dzenje la pansi la ulusi, kupyolera mu dzenje kapena dzenje lakhungu;

3, kukonzedwa workpiece zakuthupi ndi kuuma;

4, workpiece wathunthu ulusi kuya ndi pansi dzenje kuya;

5, workpiece ulusi mwatsatanetsatane;

6, mawonekedwe amtundu wapampopi (zofunikira zapadera ziyenera kulembedwa).

Nthawi yotumiza: Sep-22-2022